日志

William Edwards Deming a Total Quality Management Thinker

|

W Edwards Deming

Your use of this content is subject to the terms and conditions of this portal

William Edwards Deming (1900-1993) is widely acknowledged as the leading management thinker in the field of quality. He was a statistician and business consultant whose methods helped hasten Japan’s recovery after the Second World War and beyond. He derived the first philosophy and method that allowed individuals and organisations to plan and continually improve themselves, their relationships, processes, products and services. His philosophy is one of cooperation and continual improvement; it avoids blame and redefines mistakes as opportunities for improvement.

Life and career

Born in Iowa in 1900, Deming’s modest upbringing in an early settler community was to instil habits of thriftiness and a dislike of waste which was to influence his later thinking. His University career started at the University of Wyoming where he achieved an engineering degree in 1921, followed by a Masters in mathematics and physics from the University of Colorado. He completed his studies at Yale University in 1928, where he was awarded a doctorate in mathematical physics. Deming then concentrated on lecturing and writing in mathematics, physics and statistics for the next 10 years.

In the late 1920s Deming became familiar with the work of Walter Shewhart, who was experimenting with the application of statistical techniques to manufacturing processes. Deming became interested in applying Shewhart's techniques to non-manufacturing processes, particularly clerical, administrative and management activities. After joining the US Census Bureau in 1939 he applied statistical process control to their techniques, which contributed to a six-fold improvement in productivity. Around this time, Deming started to run courses for engineers and designers on his - and Shewhart's - evolving methods of statistical process control. At Stanford, Deming taught the Stanford statistic training program to nearly 2,000 people in a couple of years, using the Shewhart Cycle for Learning and Improvement and the PDCA Cycle.

Deming's expertise as a statistician was instrumental in his posting to Japan after the Second World War as an adviser to the Japanese Census. At this time, the USA was the leading economic power, with products much envied by the rest of the world; it saw no need for Deming's new ideas. The Japanese, on the other hand, recognised that their own goods were shoddy by international comparison. Moreover, after the war, they could not afford the wastage of raw materials that post-production inspection processes brought about and were consequently looking for techniques to help them address these problems. Whilst in Japan, Deming became involved with the Union of Japanese Scientists and Engineers (JUSE) and his career of lecturing to the Japanese on statistical methods and company-wide quality: a combination of techniques now known as Total Quality Management (TQM) had begun.

It was only in the late 1970s that the USA became aware of his achievements in Japan. The 1980s saw a spate of publications explaining his work and influence. In his American seminars during 1980, Deming talked of the need for the total transformation of the Western style of management. In 1986 he published Out of the crisis which documented the thinking and practice that had led to the transformation of Japanese manufacturing industry. Just before he died in 1993 he founded the W. Edwards Deming Institute.

Key theories

Summary

Deming's work and writing constitute not so much a technique, as a philosophy of management, Total Quality Management, that focuses on quality and continuous improvement but which has had - justifiably - a much wider influence.

Here we will consider Deming's interest in variation and his approach to systematic problem solving which led on to his development of the 14 points which have gained widespread recognition and which are central to the quality movement and his philosophy of transformational management. Deming’s seven deadly diseases of management and his use and promotion of the PDCA cycle, known to many as the Deming Wheel, are described below:

Variation and problem solving

The key to Deming's ideas on quality lies in his recognition of the importance of variation. In Out of the crisis he states:

'The central problem in management and in leadership...is failure to understand the information in variation'.

Deming was preoccupied with why things do not behave as predicted. All systems (be they the equipment, the process or the people) have variation, but he argued that it is essential for managers to be able to distinguish between special and common causes of variation. He developed a theory of variation - that special causes of variation are usually easily attributable to quickly recognisable factors such as changes of procedure, change of shift or operator etc, but that common causes will remain when special causes have been eliminated (normally due to design, process or system). These common causes are often recognised by workers, but only managers have the authority to change them to avoid repeated occurrence of the problem. Deming estimated that management was responsible for more than 85% of the causes of variation. This formed his central message to the Japanese.

Deming's 14 points for management

Deming created 14 points which provide a framework to developing knowledge in the workplace and can be used to guide long term business plans and aims. The points constitute not so much an action plan as a philosophical code for management. They have been extensively interpreted by as many commentators on quality, as on other management disciplines.

Deming's 14 points

- Create constancy of purpose toward improvement of product and service, with the aim of becoming competitive, staying in business and providing jobs.

- Adopt the new philosophy. Western management must awaken to the challenge, must learn their responsibilities and take on leadership for change.

- Cease dependence on mass inspection. Build quality into the product from the start.

- End the practice of awarding business on the basis of price tag alone. Instead, minimise total cost. Move towards a single supplier for any item, based on a long-term relationship of loyalty and trust.

- Improve constantly and forever the system of production and service to improve quality and reduce waste.

- Institute training and retraining.

- Institute leadership. The aim of supervision should be to lead and help people to do a better job.

- Drive out fear so that everyone may work effectively for the company.

- Break down barriers between departments. People in research, design, sales and production must work as a team, to foresee and solve problems of production.

- Eliminate slogans, exhortations and targets for the workforce as they do not necessarily achieve their aims.

- Eliminate numerical quotas in order to take account of quality and methods, rather than just numbers.

- Remove barriers to pride of workmanship.

- Institute a vigorous program of education and re-training for both the management and the workforce.

- Take action to accomplish the transformation. Management and workforce must work together.

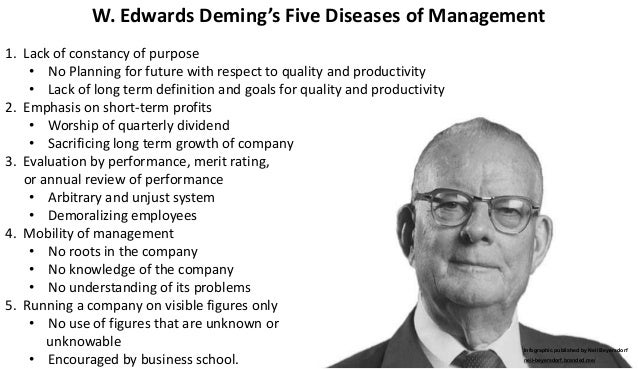

Deming's seven deadly diseases of management

Here, Deming describes the main barriers faced by management to improving effectiveness and continual improvement. He was referring here to US industry and their management practices.

- Lack of constancy of purpose to plan products and services that will have a market and keep the company afloat.

- An emphasis on short term profits and short term thinking (just the opposite from constancy of purpose to stay in business), fed by fear of unfriendly takeover, and by demand from bankers and owners for dividends.

- Evaluation of performance and annual reviews.

- Mobility of managers and job hopping.

- Management by use only of available data.

- High medical costs.

- High costs of liability.

Deming said that effective management and a commitment to quality were needed to combat these seven deadly diseases. He emphasised the importance of communicating quality messages to all staff and building a belief in total quality management.

The relevance of these principles to a wider general management application has contributed to Deming's status as a founder of the Quality Management movement, not just quality and process control. This is why he interests an audience that is much wider than the quality lobby.

PDCA Cycle (The Deming Wheel)

Walter Shewhart originated the concept of the PDCA cycle and introduced it to Deming. Deming promoted the idea widely in the 1950s and it became known as the Deming Wheel or the Deming cycle.

The PDCA (Plan-Do-Check-Act) cycle consists of four steps or stages which must be gone through to get from `problem-faced' to `problem solved.’ Repetition of these steps forms a cycle of continual improvement:

Plan for changes to bring about improvement.

Do changes on a small scale first to trial them.

Check to see if changes are working and to investigate selected processes.

Act to get the greatest benefit from change.

In perspective

Naturally enough, no one as universally acclaimed as Deming will escape without criticism. Some have criticised his approach as being good for improvement, but uninspiring for creativity and innovation. Others say his approach is not effective for generating new products or penetrating new markets.

Others, particularly Joseph Juran, another quality guru, comment on an over-reliance on statistical methods. Deming's US lectures in the 1980s, however, point time and time again to a mistaken preoccupation with the wrong type of statistics. He argued against figures focusing purely on productivity and control and argued for more evidence of quality, a message which Tom Peters adopted in the 1980s and 1990s.

Deming has stirred up wide interest with his denial of Management by Objectives and performance appraisals. Similarly, his attitude towards integrating the workforce has led TQM to be perceived as a caring philosophy. Paradoxically, his focus on cost-reduction has been pointed to as a cause of downsizing.

Although in the 1980s the US paid tribute to Deming - not only for what he did in Japan, but also for his thinking and approach to quality management - few American companies used his methods. One reason for this is perhaps that by the 1980s Deming was selling a system that worked, that he implied that he had discovered the only way to achieve quality, and that he was no longer alert to changes in the problems. In Japan, in the beginning, he had listened to Japanese needs and requirements, showed them respect and developed his thinking with them. With the USA in the early 1980s, he appeared to try to dispense his philosophy rather than adapt it to a different culture.

In 1951, in early recognition of their debt to Deming, the JUSE awarded the Deming prize to Japanese organisations excelling in company-wide quality. It was not until the late 1980s that the US recognised Deming's achievements in Japan and elevated him rapidly to guru status. The 1990s showed Deming's legacy is likely to have both a lasting and significant impact on management theory. Why is this?

The first reason must lie in the nature of his achievement. Deming has been universally acclaimed as one of the Founding Fathers of Total Quality Management, if not the Founding Father. The revolution in Japanese manufacturing management that led to the economic miracle of the 1970s and 1980s has been attributed largely to Deming.

Secondly, if the 14 points make less of an impact today than they did just after the Second World War in Japan, it is probably because many aspects of those points have now been adopted, assimilated and integrated into management practice in the 1990s as well as continuously debated and taught in Business Schools around the world.

The third reason is more complex, and lies in the scope of his legacy. Deming's 14 points add up to a code of management philosophy which spans the two major schools of management thought which have dominated since the early 20th century: scientific (hard) management on the one hand, and human relations (soft) management on the other. Deming succeeds - despite criticisms of overuse of statistical techniques - in marrying them together. Over half of his 14 points focus on people as opposed to systems. Many management thinkers veer towards one school or the other. Deming, like Drucker, melds them together.

The originality and freshness of Deming is that he took his philosophy, not from the world of management, but from the world of mathematics, and wedded it with a human relations approach which did not come from management theory but from observation, and from seeing what people needed from their working environment in order to contribute of their best.

Work in Japan - W. Edwards Deming - Wikipedia

In 1947, Deming was involved in early planning for the 1951 Japanese Census. The Allied powers were occupying Japan, and he was asked by the United States Department of the Army to assist with the census. He was brought over at the behest of General Douglas MacArthur, who grew frustrated at being unable to complete so much as a phone call without the line going dead due to Japan's shattered post-war economy. While in Japan, his expertise in quality control techniques, combined with his involvement in Japanese society, brought him an invitation from the Japanese Union of Scientists and Engineers (JUSE).[10]

JUSE members had studied Shewhart's techniques, and as part of Japan's reconstruction efforts, they sought an expert to teach statistical control. From June–August 1950, Deming trained hundreds of engineers, managers, and scholars in statistical process control (SPC) and concepts of quality. He also conducted at least one session for top management (including top Japanese industrialists of the likes of Akio Morita, the cofounder of Sony Corp.)[17] Deming's message to Japan's chief executives was that improving quality would reduce expenses while increasing productivity and market share.[4] Perhaps the best known of these management lectures was delivered at the Mt. Hakone Conference Center in August 1950.

A number of Japanese manufacturers applied his techniques widely and experienced heretofore unheard-of levels of quality and productivity. The improved quality combined with the lowered cost created new international demand for Japanese products.

Deming declined to receive royalties from the transcripts of his 1950 lectures, so JUSE's board of directors established the Deming Prize (December 1950) to repay him for his friendship and kindness.[17]Within Japan, the Deming Prize continues to exert considerable influence on the disciplines of quality control and quality management.[18]

Honors - W. Edwards Deming - Wikipedia

In 1960, the Prime Minister of Japan (Nobusuke Kishi), acting on behalf of Emperor Hirohito, awarded Deming Japan's Order of the Sacred Treasure, Second Class.[19] The citation on the medal recognizes Deming's contributions to Japan's industrial rebirth and its worldwide success. The first section of the meritorious service record describes his work in Japan:[17]

- 1947, Rice Statistics Mission member

- 1950, assistant to the Supreme Commander of the Allied Powers

- instructor in sample survey methods in government statistics

The second half of the record lists his service to private enterprise through the introduction of epochal ideas, such as quality control and market survey techniques.

Among his many honors, an exhibit memorializing Deming's contributions and his famous Red Bead Experiment is on display outside the board room of the American Society for Quality.[20]

He was inducted into the Automotive Hall of Fame in 1991.

Later work in the U.S. - W. Edwards Deming - Wikipedia

David Salsburg wrote:

- "He was known for his kindness to and consideration for those he worked with, for his robust, if very subtle, humor, and for his interest in music. He sang in a choir, played drums and flute, and published several original pieces of sacred music."[21][22]

Later, from his home in Washington, D.C., Deming continued running his own consultancy business in the United States, largely unknown and unrecognized in his country of origin and work. In 1980, he was featured prominently in an NBC TV documentary titled If Japan can... Why can't we? about the increasing industrial competition the United States was facing from Japan. As a result of the broadcast, demand for his services increased dramatically, and Deming continued consulting for industry throughout the world until his death at the age of 93.

Ford Motor Company was one of the first American corporations to seek help from Deming. In 1981, Ford's sales were falling. Between 1979 and 1982, Ford had incurred $3 billion in losses. Ford's newly appointed Corporate Quality Director, Larry Moore, was charged with recruiting Deming to help jump-start a quality movement at Ford.[23] Deming questioned the company's culture and the way its managers operated. To Ford's surprise, Deming talked not about quality, but about management. He told Ford that management actions were responsible for 85 percent of all problems in developing better cars. In 1986, Ford came out with a profitable line of cars, the Taurus-Sable line. In a letter to Autoweek Magazine, Donald Petersen, then Ford chairman, said, "We are moving toward building a quality culture at Ford and the many changes that have been taking place here have their roots directly in Deming's teachings."[24] By 1986, Ford had become the most profitable American auto company. For the first time since the 1920s, its earnings had exceeded those of archrival General Motors (GM). Ford had come to lead the American automobile industry in improvements. Ford's following years' earnings confirmed that its success was not a fluke, for its earnings continued to exceed GM and Chrysler's.

In 1982, Deming's book Quality, Productivity, and Competitive Position was published by the MIT Center for Advanced Engineering, and was renamed Out of the Crisis in 1986. In it, he offers a theory of management based on his famous 14 Points for Management. Management's failure to plan for the future brings about loss of market, which brings about loss of jobs. Management must be judged not only by the quarterly dividend, but by innovative plans to stay in business, protect investment, ensure future dividends, and provide more jobs through improved products and services. "Long-term commitment to new learning and new philosophy is required of any management that seeks transformation. The timid and the fainthearted, and the people that expect quick results, are doomed to disappointment."

In 1982, Deming, along with Paul Hertz and Howard Gitlow of the University of Miami Graduate School of Business in Coral Gables, founded the W. Edwards Deming Institute for the Improvement of Productivity and Quality. In 1983, the institute trained consultants of Ernst & Whinney Management Consultants in the Deming teachings. E&W then founded its Deming Quality Consulting Practice which is still active today.

Over the course of his career, Deming received dozens of academic awards, including another, honorary, PhD from Oregon State University. In 1987, he was awarded the National Medal of Technology: "For his forceful promotion of statistical methodology, for his contributions to sampling theory, and for his advocacy to corporations and nations of a general management philosophy that has resulted in improved product quality." In 1988, he received the Distinguished Career in Science award from the National Academy of Sciences.[10]

Deming and his staff continued to advise businesses large and small. From 1985 through 1989, Deming served as a consultant to Vernay Laboratories, a rubber manufacturing firm in Yellow Springs, Ohio, with fewer than 1,000 employees. He held several week-long seminars for employees and suppliers of the small company where his infamous example "Workers on the Red Beads" spurred several major changes in Vernay's manufacturing processes.

Deming joined the Graduate School of Business at Columbia University in 1988. In 1990, during his last year, he founded the W. Edwards Deming Center for Quality, Productivity, and Competitiveness at Columbia Business School to promote operational excellence in business through the development of research, best practices and strategic planning.

In 1990, Marshall Industries (NYSE:MI, 1984–1999) CEO Robert Rodin trained with the then 90-year-old Deming and his colleague Nida Backaitis. Marshall Industries' dramatic transformation and growth from $400 million to $1.8 billion in sales was chronicled in Deming's last book The New Economics, a Harvard Case Study, and Rodin's book, Free, Perfect and Now.

In 1993, Deming published his final book, The New Economics for Industry, Government, Education, which included the System of Profound Knowledge and the 14 Points for Management. It also contained educational concepts involving group-based teaching without grades, as well as management without individual merit or performance reviews.

Deming died in his sleep at the age of 93 in his Washington home from cancer on December 20, 1993. [25] When asked, toward the end of his life, how he would wish to be remembered in the U.S., he replied, "I probably won't even be remembered." After a pause, he added, "Well, maybe ... as someone who spent his life trying to keep America from committing suicide."[26]

Further reading

Key works by Deming

Books

Out of the crisis: quality, productivity and competitive position.Cambridge, Cambridge University Press, 1986

The new economics for industry, government and education.(2nd ed.) Cambridge, Mass., MIT Press, 2000

Key works by others

Books

Aguayo, R. Dr Deming: The American who taught the Japanese about quality. London, Mercury Books, 1991

Bendell, T. The quality gurus. London, Department of Trade and Industry, 1991

Drummond, H. The quality movement: what total quality management is really all about. London, Kogan Page, 1992

Logothetis, N. Managing for total quality: from Deming to Taguchi and SPC. New York, Prentice Hall, 1992

Witzel, M. Management from the masters. London, Bloomsbury, 2014

Liker, J. and Franz, J. The Toyota way to continuous improvement: linking strategy and operational excellence to achieve superior performance. New York, McGraw-Hill, 2011

Journal articles

Pyke, W. Is performance personal or in the system? Management Services. 52 (4), Winter 2008, pp.40-47

Seddon, J. and O’Donovan, B. Rethinking lean service. Management Services, 54 (1), Summer 2010, pp.34-37

Websites

The W Edwards Deming Institute

https://deming.org/